There are many different methods and steps involved in the production of textiles. Each material has its own unique production process and set of standards and specifications that must be met in order to ensure a high-quality product.

Regardless of the type of material used, there are three basic steps involved in textile production:

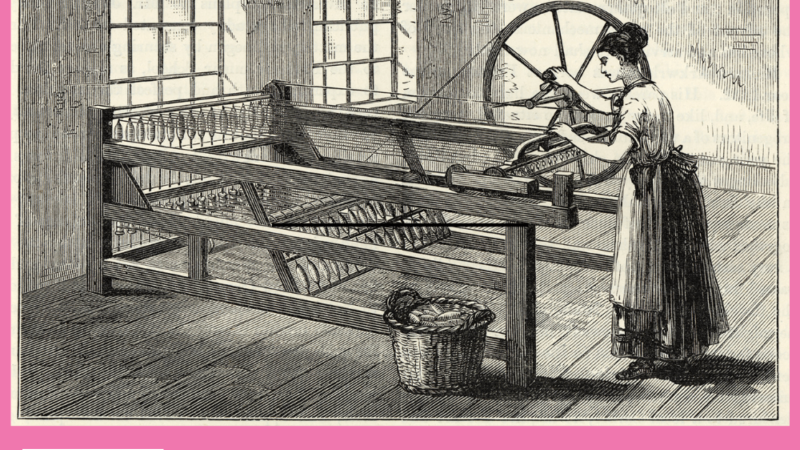

- Fiber Conversion: The raw harvested material is converted from loose fibers into yarn. This can be done either manually or mechanically using a spinning wheel. The fibers are drawn out through the spinning wheel, which is rotated to create tension. The fibers are then collected onto a spool, which holds the spun yarn and combines the individual fibers into a single long thread. The yarn is then wound onto large spools.

- Weaving or Knitting: The long individual threads or yarns are woven or knitted together to create a cohesive fabric. This is done using a loom, which requires two sets of threads: one set running lengthwise (warp) and the other running crosswise (weft). The loom tensions the threads across a large metal frame and interweaves them using a system of rods and pedals. The process is controlled by a computer connected to the loom.

- Finishing: The fabric is removed from the loom and prepared for the next step. It is treated with specific chemicals to make it look like clean, white sheets that are flexible and soft, similar in texture to familiar clothing. This process removes impurities, seed particles, and other contaminants. The fabric is then treated again to remove any oils, waxes, or other substances that are typically present in natural fibers. The textiles are then dyed and shipped to other factories for use in clothing, furniture, and other applications.

Optional Finishing Treatment:

In an additional optional step, the fabric can be treated one last time before use to protect the added color. Dyed clothing tends to fade over time or with exposure to water and other elements. These additives act as a protective shield for the textile fabric. They form a layer on top of the color without affecting it. Instead, they add a visual sheen that reflects light off the fabric, making the colors appear brighter and more vibrant. This helps the fabric retain its new appearance for a longer period.